Semi Automatic Block Making Maching – QT4-24 Series

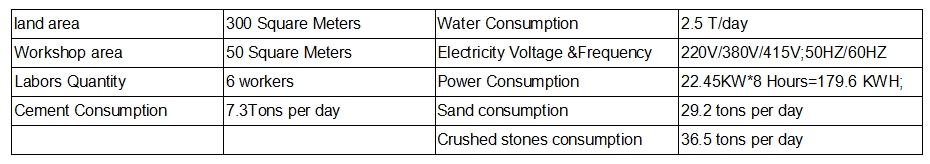

1. QT4-24 Cement Brick Machine line Basic requirements for Start this brick plant:

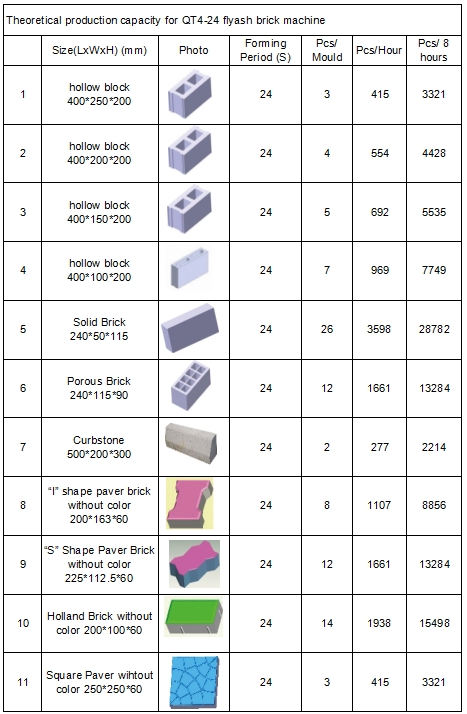

The following information for QT4-24 hollow block machine is theoretically for reference, it will be a little different vary from different clients as per their real production conditio

2.Detailed Introduction of each single machine from QT4-24 block machine line

(1) JQ350 concrete mixer for QT4-24 Paver Brick Machine Diameter 1.2 M Power: 7.5-4KW or 5.5-6KW Input : 500L Output: 350L Dimension: 1.2*1.2*1.4 M Weight: 350KG

Pan Mixer RAYTONE block machine factory is using truck rear axle instead of normal gear reducer more now; this makes the concrete mixer stronger and more durable. The buyer can also fix one 10 CM round steel plate on the top of the mixer, in order to avoid the raw materials coming out when the mixing blades are at high rotating speed. Also there are Two ways to make the mixer more anti-friction Fix the spacers on the interior and bottom of the pan mixer, the spacers can be replaced by spare. The spacers can be changed one by one if any is broken, but adding spacers is a little costly; The second method is to Fix one round steel sheet inside the pan mixer, this will also increase the sturdiness.

(2)6 M belt conveyor for QT4-24 Cement Brick Machine Power: 1.5 KW Type: Chain type Belt width: 400mm Length: 6 M; Client can also choose 7 meters or 8 Meters length belt

(3) QT4-24 Host Flyash BrickMachine Power: 13.45KW

Raw materials discharging motor: 0.75KW

Bottom Vibration Motor 3KW*2

Upper Vibration Motor 2.2KW

JQ350 Reducer Mould lifting Motor: 3KW

Top Mould Push-Pull motor: 0.75KW

Block Conveying out motor:0.75 KW

Dimension: 2050*1900*2650mm

Weight:1800KG

RAYTONE block machine factory is using JZQ350 reducer for the brick machine instead of using JZQ250 reducer. Better Control System: The raw materials are automatically fed in the bottom mould, then need to spread raw materials evenly, then press MOULD IN button, once top mould is going into bottom mould, the bottom gearbox vibrating box will vibrate automatically and the top vibrator also vibrate at the same time, after vibration is done, the top mould automatically lift up. then block is conveyed automatically. The work efficiency is much improved, no need to press the buttons on the electric cabinet for every movement. Automatic feeding raw material, Automatic pull-push mould, automatic blocks conveying out, This is how this block machine is called Semi Automatic Block Machine.

(4)Brick Conveyor Trolley for QT4-24 Semi Automatic Block Machine :The manual block conveying trolley is used to carry the finished blocks to curing area. One block machine line is with two sets of manual block conveying carts.

(5) Block Stacking Machine :(this is upgraded configuration, equipment with this stacking Machine, no need the manual brick conveyor trolley, but need an electric forklift to carry stacked blocks to curing area. Or use the manual trolley dedicated for stacking machine)

Power: 1.5 KW

Dimension:1.75*1.75*2.3 M

Weight: 500KG

(6) GMT brick pallets supported for QT4-24 brick machine Life: 8 years Density: 1200kg/Cubic meters GMT pallet is the most popular and cost to performance pallet now. Pallet size: 850*550*22mm

3.Productivity of QT4-24 Cement Block Machine

4.The blocks made from QT4-24 Brick Making Machine

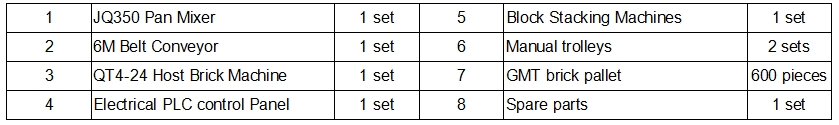

5.Packing List of QT4-24 Block Machine

6.Our Service

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation letter for you.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

7.Guarantee

We can supply one year guarantee period for our brick making machines,if the

client have the question ,they could call our service department number any time ,

we will supply per day 24 hours service .