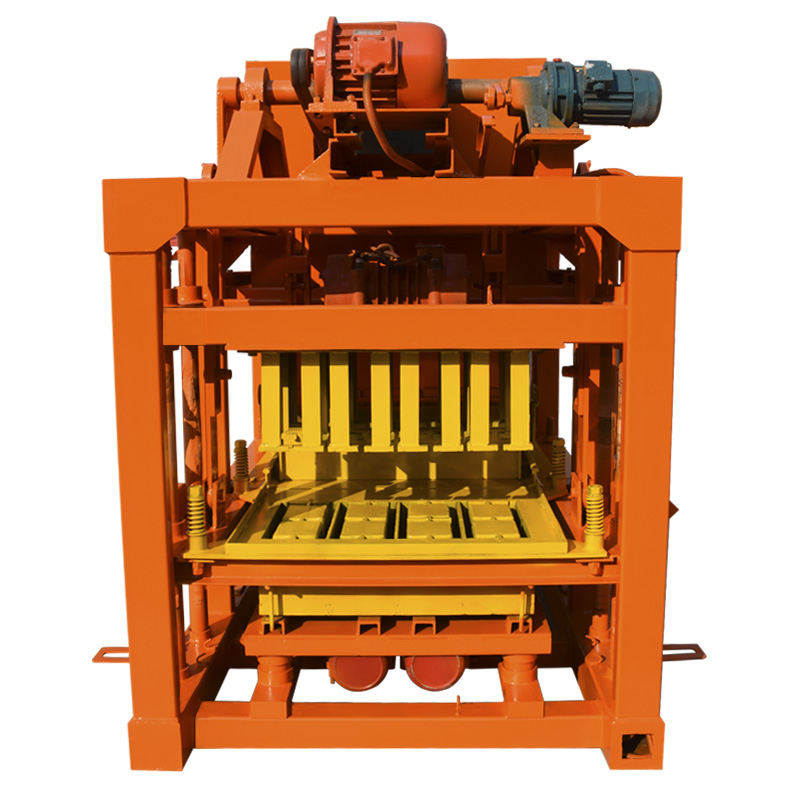

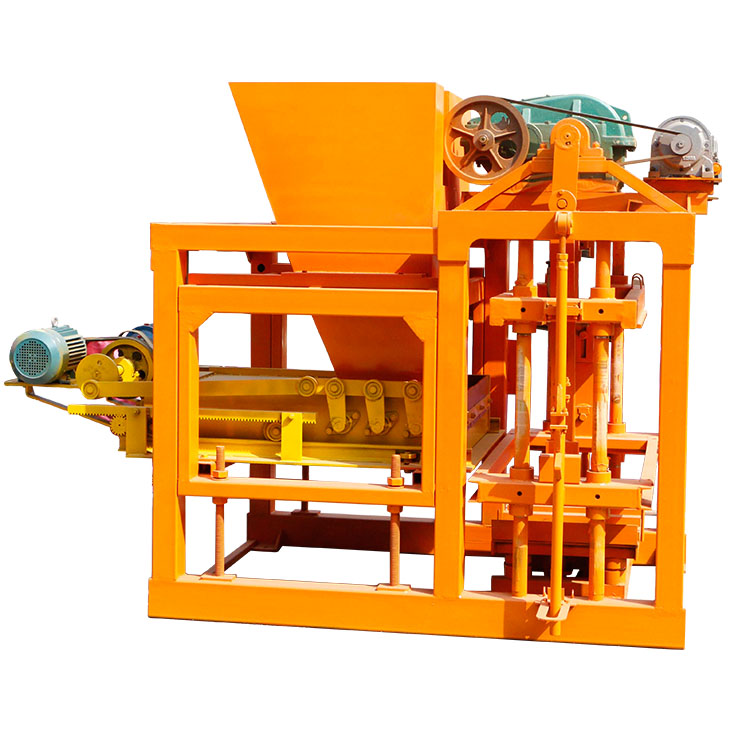

QT4-28 Semi Automatic Block Machine

Hollow Block Making Machine QT4-28 Model

1. QT4-28 hollow block making machine advantages:

(1) Easy installation and operation The QT4-28 hollow block making machine just need to set up the belt conveying machine, and connect with power source, then can start operation.

(2) Low investment, RAYTONE QT4-28 hollow block making machine price are competitive, and its price is much better than simple automatic QT4-25 block machine and QT4-18 Block Making Machine.

(3) Simple Design The QT4-28 hollow block making machine is a simple structure,three is no pallet feeding device and block conveying out section, they pallet feeding is by hand, and finished blocks are take out by manual trolley.

(4) QTJ4-28 Semi-automatic brick making machine is specially designed for medium scale block project. It’s automatic materials feeding, distributing, brick forming. This model block machine is very economical, popular in developing countries.

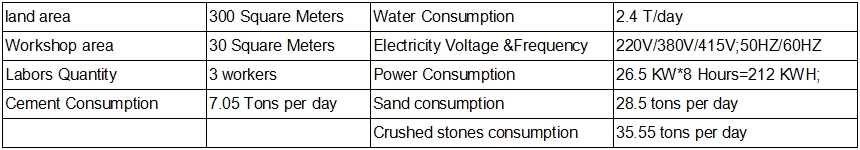

2.Basic Requirements for Start Up QT4-28 Hollow Block Making Machine:

3.Each machine for QT4-28 Hollow Block Making Machine line:

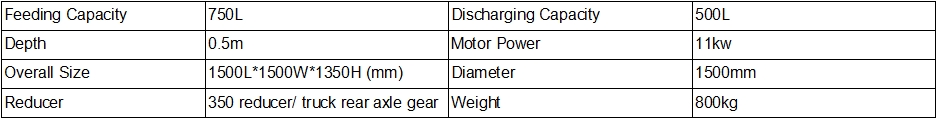

(1) JQ500 concrete mixer :

(2) 6 Meters length belt conveying machine

Motor power: 1.5KW

Length: 6 Meters

Width: 400mm

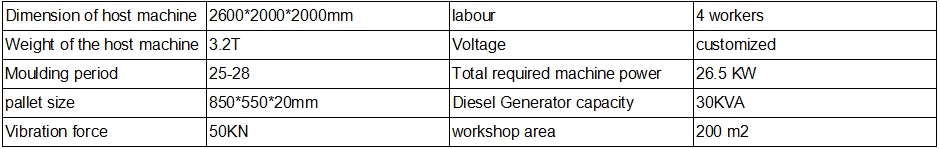

(3) QT4-28 Host block making machine:

QT4-28 is mechanical vibration type baking-free manual block machine. It has 2 sets of bottom vibration motor of 3 KW, top vibration motor of 1 set 2.2 KW, Raw materials distributing motor of 2.2 KW Top mould fall down motor: 1.1KW Block mould lift motor: 3.0 KW push-pull mould by electric. dosing material at a time, easily operated, Regular production use 4 workers, one worker control mixer, one operate the host machine, two take charge of transporting formed blocks.

(4) Manual block trolley Used to transport the finished block to curing area.

(5) GMT Brick pallets

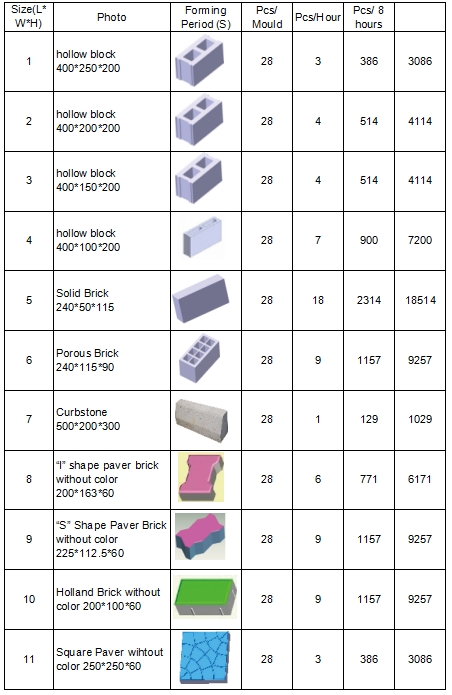

4.Daily productivity of QT4-28 Hollow Block Making Machine

5. FAQ

(1) Can this QT4-28 hollow block making machine make other types paver bricks, interlocking bricks? Yes, this QT4-28 block machine can also make various shape and different size blocks brick under different block moulds.

(2) What is the raw materials and their formula for making the concrete blocks by QT4-28 hollow block making machine, The raw materials are cement ,concrete ,sand ,fly ash ,construction waste, coal gangue, slag, mountain flour. The formula of raw material is cement 8%-10% sand 30%-40% stone:50%-60%,about cement :sand : stone is1:4:5.

(3) What is the normal hollow block weight? For the hollow block weight: 8 inch (400*200*200) block is 17KG, 6 inch (400*150*200) block is 13.5KG, 4 inch (400*100*200) block is 10KG.

6.Our Service

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service.

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation letter for you.

Sale:

(1) Update the production scheduling in time.

(2) Quality supervision.

(3) Product acceptance.

(4) Shipping on time.

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate.

(3) offer training to the operator.

(4) Skill support the whole using life.

(5) Recall clients regularly,get feedback in time ,keep well communication with each other

7.Guarantee

We can supply one year guarantee period for our brick making machines,if the

client have the question,they could call our service department number any time,

we will supply per day 24 hours service.